If you own a boiler, you know how important it is to keep it running smoothly. Unfortunately, like any other appliance, boilers can develop problems over time. Knowing how to identify and troubleshoot common boiler issues can help you avoid costly repairs and keep your home warm and comfortable.

One of the most common boiler problems is a lack of heat or hot water. This can be caused by a variety of issues, including a malfunctioning thermostat, low water pressure, or a faulty pilot light. If you’re experiencing this problem, it’s important to troubleshoot the issue as soon as possible to avoid further damage to your system.

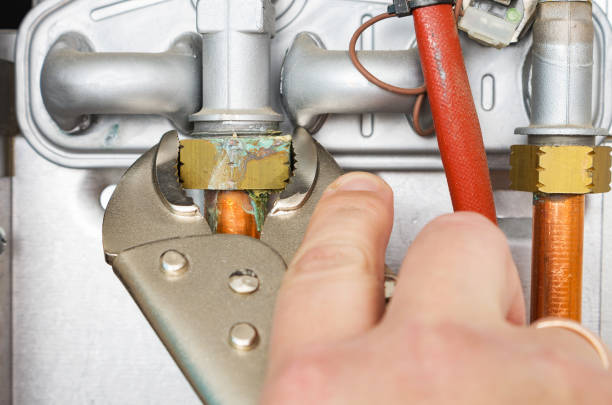

Another common issue is a leaking or dripping boiler. This can be caused by a variety of factors, including corrosion, worn-out seals, or a faulty expansion tank. If you notice water pooling around your boiler, it’s important to address the issue immediately to prevent damage to your home and system.

Understanding Boilers

Boilers are an essential part of many industrial processes and are used to generate steam or hot water for heating, power generation, and other applications. Understanding how boilers work and how to maintain them is crucial to ensure their safe and efficient operation.

Boiler Types

- Combi Boilers:

Combi boilers, also known as combination boilers, are popular for their compact size and efficiency. These boilers provide heating and hot water from a single unit, eliminating the need for separate hot water cylinders or tanks. However, they are primarily suitable for smaller properties with lower hot water demands. Some common issues with combi boilers include:

- Limited hot water flow rates: Due to their compact size, combi boilers may experience lower hot water flow rates when multiple outlets are in use simultaneously. This can result in reduced water pressure and slower hot water delivery.

- Pressure fluctuations: Combi boilers are susceptible to pressure fluctuations, which can lead to issues such as inconsistent heating or hot water supply. Regular monitoring and maintenance of the pressure levels are necessary to ensure optimal performance.

- Conventional Boilers:

Conventional boilers, also referred to as regular or heat-only boilers, have been a traditional choice for larger properties with higher hot water demands. They require separate hot water cylinders and tanks for heating and hot water supply. Common issues associated with conventional boilers include:

- Aging components: As conventional boilers are often found in older properties, their components may be prone to wear and tear over time. Common issues include faulty valves, leaks in the cylinders or tanks, and general deterioration of the system.

- Inefficiency: Compared to modern boiler types, conventional boilers may be less energy-efficient. They can experience heat loss through the hot water cylinders and tanks, leading to higher energy consumption and increased heating costs.

- System Boilers:

System boilers are similar to conventional boilers but have built-in pumps and valves. They are commonly paired with unvented hot water cylinders to improve flow rates and are suitable for properties with high hot water demands. However, system boilers can face the following common issues:

- Pump failure: The built-in pump in a system boiler can sometimes fail, resulting in poor circulation of hot water throughout the system. This can lead to reduced heating performance or insufficient hot water supply.

- Pressure loss: System boilers rely on proper water pressure to function effectively. Issues such as water leaks or faulty pressure relief valves can cause pressure loss, resulting in heating and hot water problems.

Boiler Components

Boilers consist of several components that work together to produce steam or hot water. Some of the key components include:

- Burner: This component is responsible for igniting the fuel and producing the flame that heats the water.

- Heat exchanger: This component transfers heat from the burner to the water.

- Water level control: This component ensures that the water level in the boiler remains at the desired level.

- Pressure relief valve: This component releases excess pressure from the boiler to prevent damage.

Common Boiler Issues

Boilers can experience a range of issues that can impact their performance and safety. Some of the most common issues include:

- Scale buildup: This can occur when minerals in the water accumulate on the heat exchanger, reducing its efficiency.

- Corrosion: This can occur when the metal components of the boiler are exposed to water and oxygen, leading to rust and other damage.

- Pressure problems: Boilers can experience issues with low or high pressure, which can impact their efficiency and safety.

- Fuel supply issues: Boilers that use gas or oil for fuel can experience issues with the supply of fuel, leading to problems with ignition and combustion.

By understanding the different types of boilers, their components, and the common issues they can experience, you can take steps to ensure their safe and efficient operation. Regular maintenance and inspections can help to identify and address issues before they become more serious.

Common Boiler Issues

Boilers are an essential part of any home heating system, but they can develop issues that can cause inconvenience and discomfort. Here are some of the most common boiler issues that you may encounter.

Leaking and Dripping

Leaking and dripping are common boiler problems that can occur due to a variety of reasons, such as a faulty pressure valve or pump seal. If you notice water surrounding your boiler tank or the pipes connected to it, it’s a sign of a leak. The issue needs to be addressed immediately, as it can cause damage to your property and lead to increased energy bills.

Strange Noises

If you hear strange noises coming from your boiler, such as banging, whistling, or gurgling sounds, it’s a sign of a problem. The issue could be due to trapped air in the system, kettling, or a faulty pump. Ignoring the problem can lead to further damage and higher repair costs.

Low Pressure

Low boiler pressure can cause your heating system to stop working, and it’s a common issue that can be caused by a leak in the system or a faulty pressure valve. If you notice that the pressure gauge on your boiler is below the recommended level, you need to top up the pressure immediately.

Frozen Condensate Pipe

During winter, the condensate pipe that carries waste water from your boiler to the outside can freeze, causing your boiler to shut down. If you notice that your boiler has stopped working during cold weather, it’s likely due to a frozen condensate pipe. You can thaw the pipe using warm water or a hot water bottle, but it’s best to call a qualified engineer to fix the issue.

No Heat or Hot Water

If your boiler is not producing heat or hot water, it’s a sign of a problem. The issue could be due to a faulty thermostat, a broken diaphragm, or a blocked pipe. It’s best to call a qualified engineer to diagnose and fix the problem.

Boiler Kettling

Boiler kettling is a common issue that occurs when limescale builds up in the system, causing the boiler to make a rumbling or banging noise. The issue can be fixed by descaling the system, but it’s best to call a qualified engineer to do the job.

Thermostat Issues

If your boiler is not responding to your thermostat, it’s a sign of a problem. The issue could be due to a faulty thermostat, a wiring issue, or a problem with the motorised valve. It’s best to call a qualified engineer to diagnose and fix the problem.

Water too Hot

If the water coming out of your taps is too hot, it’s a sign that your boiler is overheating. The issue could be due to a faulty thermostat or a problem with the pressure valve. It’s best to call a qualified engineer to diagnose and fix the problem.

Boiler Won’t Turn On

If your boiler won’t turn on, it’s a sign of a problem. The issue could be due to a faulty pilot light, a broken diaphragm, or a problem with the motorised valve. It’s best to call a qualified engineer to diagnose and fix the problem.

Pilot Light Going Off

If your pilot light keeps going off, it’s a sign of a problem. The issue could be due to a faulty thermocouple, a blocked pilot jet, or a problem with the gas supply. It’s best to call a qualified engineer to diagnose and fix the problem.

In conclusion, these are some of the most common boiler issues that you may encounter. If you notice any of these problems, it’s best to call a qualified engineer to diagnose and fix the issue. Regular maintenance of your boiler can help prevent these issues from occurring in the first place.

Boiler Maintenance Tips

To keep your boiler running efficiently and prevent breakdowns, regular maintenance is essential. Here are some boiler maintenance tips to help you keep your boiler in top condition:

1. Schedule Annual Servicing

It is recommended that you have your boiler serviced by a qualified engineer at least once a year. Regular servicing ensures that your boiler is running efficiently, identifies any potential problems before they become major issues, and prolongs the lifespan of your boiler.

2. Check Boiler Pressure

Boiler pressure is an important factor in the efficient running of your boiler. You should check the pressure gauge regularly to ensure that the pressure is within the recommended range. If the pressure is too low, you may need to top up the system with water. If the pressure is too high, you should contact a qualified engineer.

3. Bleed Radiators

If your radiators are not heating up properly, this could be a sign that there is air trapped in the system. Bleeding your radiators will release any trapped air and improve the efficiency of your heating system. You can do this yourself by using a radiator key to release the air.

4. Keep Boiler Area Clear

Make sure that the area around your boiler is clear of clutter and debris. This will allow air to circulate freely and prevent the build-up of dust and dirt, which can affect the efficiency of your boiler.

5. Check Boiler Flue

The boiler flue is the pipe that carries waste gases away from your boiler. It is important to check that the flue is clear of debris and in good condition to prevent the build-up of harmful gases, such as carbon monoxide. You should also ensure that the flue is not blocked by snow or ice during the winter months.

By following these boiler maintenance tips, you can help to keep your boiler running efficiently and prevent breakdowns. Remember, if you are ever in doubt about any aspect of boiler maintenance, always consult a qualified engineer.

When to Call a Professional

If you are experiencing any of the following issues with your boiler, it is best to call a professional for assistance:

- No heating or hot water: This is one of the most common issues with boilers. If your boiler is not providing any heat or hot water, it could be due to a variety of reasons such as a faulty thermostat, a broken pump, or a malfunctioning valve. A professional can diagnose the issue and provide the necessary repairs.

- Low pressure: If your boiler’s pressure is too low, it can cause it to stop working. While you can try to increase the pressure yourself, it is best to call a professional to avoid causing any damage to your boiler.

- Strange noises: If your boiler is making strange noises such as banging, gurgling, or whistling, it could be due to trapped air, a faulty pump, or a build-up of limescale. A professional can identify the cause of the noise and provide the necessary repairs.

- Leaks: If you notice any leaks coming from your boiler, it is important to call a professional immediately. Leaks can cause serious damage to your property and can also be a safety hazard.

- Pilot light issues: If your boiler’s pilot light keeps going out or is not lighting at all, it could be due to a faulty thermocouple or a blocked pilot jet. A professional can diagnose the issue and provide the necessary repairs.

Remember, attempting to fix your boiler yourself can be dangerous and can cause further damage to your boiler. Always call a professional if you are unsure about any repairs or if you are experiencing any of the issues mentioned above.

FAQ

Q: What are the most frequent causes of boiler breakdowns?

A: The most frequent causes of boiler breakdowns include issues with the thermostat, pressure problems, faulty ignition, and pump or valve failures.

Q: What are the signs of a faulty boiler?

A: Signs of a faulty boiler can include strange noises, irregular heating or hot water supply, frequent pilot light extinguishing, water leaks, and a noticeable increase in energy bills.

Q: How can I troubleshoot my combi boiler?

A: To troubleshoot a combi boiler, you can check the thermostat settings, ensure the boiler has power, check for error codes, verify water pressure, and clean or replace any blocked filters.

Q: What are the common issues with Worcester boilers?

A: Common issues with Worcester boilers may include ignition problems, pressure loss, leaks in the system, faulty thermostats, and issues with the heat exchanger or diverter valve.

Q: Who should I contact for boiler repair?

A: It is recommended to contact a qualified heating engineer or a professional boiler repair service for any boiler-related issues or repairs.

Q: What are the solutions to common boiler problems?

A: Solutions to common boiler problems can include regular maintenance, checking and adjusting water pressure, cleaning or replacing filters, repairing or replacing faulty components, and ensuring proper ventilation and fuel supply. However, it is advisable to consult a professional for accurate diagnosis and repairs.