A combi boiler expansion vessel is a crucial element in your central heating system. It helps to absorb the expansion of water as it heats up, preventing damage to the boiler and maintaining the correct pressure.

However, expansion vessels can suffer from various problems that can cause leaks, loss of pressure, and other issues. In this article, we’ll explore the common problems with combi boiler expansion vessels and how to spot them.

Combi Boiler Expansion Vessel Problems

Combi boilers rely on an essential component called the expansion vessel, which manages water expansion when heated, preventing excessive pressure build-up. Problems with the expansion vessel can lead to various issues with the boiler’s performance. These issues include loss of pressure, constantly high pressure, water leaks, boiler short cycling, banging noises, insufficient hot water, and frequent safety lockouts.

If you suspect a problem with your combi boiler’s expansion vessel, it’s crucial to have it inspected and repaired by a qualified professional to ensure the system operates smoothly and safely. Regular maintenance can help prevent such problems and maintain efficient heating.

Expansion Vessel Issues

Rusting

- The expansion vessel may fail by rusting through and developing leaks. This allows water to escape from the vessel externally. Rusting is more likely if the system water lacks corrosion inhibitors or if oxygen permeates the vessel. Replacing steel vessels with plastic models can prevent this failure mode.

Perforated Diaphragm

If the rubber diaphragm separating the air and water compartments becomes perforated, it will allow water to leak through to the air side. This will cause the vessel to leak water externally.

Perforations develop as the rubber degrades over time, becoming thinner and more porous. Checking diaphragm condition during annual service can prevent this by allowing early replacement.

Failed Repressurisation Valve

The Schraeder fill valve on the expansion vessel rarely fails, but can cause problems if it does.

Degraded Diaphragm

More often, the rubber diaphragm separating the air and water degrades over time, allowing the air charge to escape. This reduces the vessel’s capacity to accommodate water expansion.

Loss of Charge Pressure

As the diaphragm degrades, charge pressure is lost, allowing water pressure to compress the air pocket further during operation. This reduces water expansion space.

Here is a step-by-step guide on how to recharge a combi boiler expansion vessel in markdown formatting:

How to Recharge a Combi Boiler Expansion Vessel

Step 1: Turn off the boiler

- Locate the power switch on the boiler and turn it off before servicing

- Shut off the gas valve that provides gas supply to the boiler

Step 2: Reduce the pressure

- Locate the filling loop or pressure relief valve on the boiler

- Open the valve slowly to release some of the water pressure in the system

- Release until the pressure gauge shows between 0.5 and 1 bar

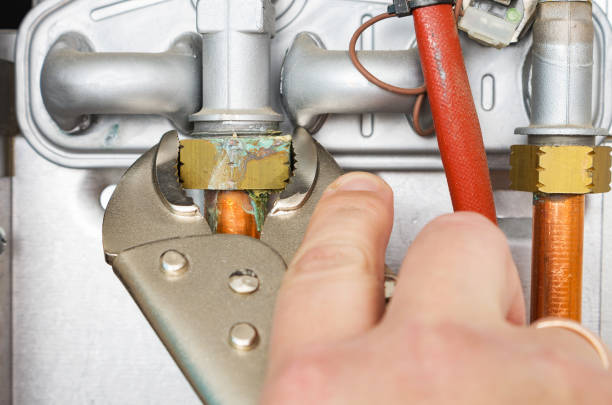

Step 3: Remove the vessel

- The expansion vessel is usually located behind the boiler or on top

- Unscrew the nut on the vessel pipe to disconnect it from the system

- Support the weight of the vessel and unscrew it from the wall bracket

Step 4: Check the charge pressure

- The vessel should have a pressure charging port

- Check the current pressure in the vessel using a tire pressure gauge

- The ideal charge pressure is around 3 bar

Step 5: Recharge the pressure

- If the pressure is lower than 3 bar, use a bicycle pump to recharge it through the charging port

- Pump slowly and keep checking the pressure until it reaches 3 bar

Step 6: Reinstall the vessel

- Place the recharged vessel back into the wall bracket and tighten screws

- Reconnect the vessel pipe to the system and tighten the nut

- Open the filling loop and repressurize system between 1 and 2 bar

Step 7: Turn boiler back on

- Double check all connections

- Restore gas and power supply to the boiler

- The system is now ready to use again

Combi Boiler Expansion Vessel Symptoms

Here are some of the most common symptoms of a problem with a combi boiler expansion vessel:

Low pressure in the central heating system

This can be a sign of a leak in the expansion vessel or a problem with the pressure relief valve.

Poor heating performance

If your central heating system is not heating your home effectively, it may be due to low pressure in the expansion vessel.

Loss of hot water

If your combi boiler is not providing hot water, it may be due to a leak in the expansion vessel or a problem with the pressure relief valve.

Water damage around the boiler

If you notice water damage around the boiler, it may be due to a leak in the expansion vessel.

Combi Boiler Expansion Vessel Replacement

Replacing a damaged or worn out expansion vessel is a vital step in maintaining the health of your central heating system. The expansion vessel in a combi boiler is responsible for absorbing the expansion of water as it heats up, maintaining the correct pressure in the system, and preventing damage to the boiler.

Over time, the diaphragm or bladder inside the vessel can become brittle and start to leak, which can lead to a loss of pressure, poor heating performance, and other issues.

To avoid these issues, it’s essential to replace your expansion vessel regularly, as recommended by the manufacturer.

When to replace: It’s recommended to replace your combi boiler expansion vessel every 7-10 years, or as recommended by the manufacturer. Some indicators that the expansion vessel may need to be replaced include:

- Loss of pressure in the central heating system

- Water dripping from the expansion vessel

- Poor heating performance

- Unusual noises from the boiler

How to replace the expansion vessel

Replacing a combi boiler expansion vessel can be a complex and time-consuming process that requires professional knowledge and experience. It’s important to follow the manufacturer’s instructions carefully, and to use the correct tools and equipment. Here’s a general outline of the steps involved in replacing a combi boiler expansion vessel:

- Turn off the power to the boiler and drain the central heating system.

- Locate the expansion vessel and remove the cap.

- Remove the old diaphragm or bladder and discard it.

- Clean the inside of the vessel and inspect it for damage.

- Install the new diaphragm or bladder, making sure to secure it in place.

- Replace the cap and refill the central heating system with water.

- Turn the power back on and test the pressure to make sure it’s within the correct range

Expansion Vessel Pressure

The pressure in your combi boiler expansion vessel is critical to the proper operation of your central heating system. If the pressure is too high, it can cause damage to the boiler and pipes, while a pressure that’s too low can result in poor heating performance.

Regular checks of the expansion vessel’s pressure can help you to spot problems early and avoid more significant damage down the line.

How to check the pressure

Checking the pressure in a combi boiler expansion vessel is a simple process that can be done with a pressure gauge. Here’s a general outline of the steps involved:

- Turn off the power to the boiler.

- Locate the pressure gauge on the central heating system and attach a pressure gauge to it.

- Turn the power back on and let the system reach normal operating temperature, which can take up to 15 minutes.

- Read the pressure gauge and compare it to the manufacturer’s recommended pressure range for your system.

It’s important to note that if the pressure is too high or too low, it may indicate a problem with the expansion vessel or another part of the central heating system, and should be addressed by a qualified professional.

Combi Boiler Expansion Vessel Leaks

Leaking expansion vessels are a common problem in combi boilers. If you notice water dripping from your expansion vessel or if your boiler pressure is dropping, these could be signs of a leak. Leaks can cause damage to your boiler and central heating system, so it’s crucial to address them as soon as possible.

A leak in the expansion vessel can occur for several reasons, including overpressure, corrosion, or a damaged diaphragm.

The signs of a leak in a combi expansion vessel can include low pressure in the central heating system, loss of hot water, and water damage around the boiler.

How to fix a leak

Fixing a leak in a combi boiler expansion vessel can be a complex process that should only be performed by a qualified professional. Here’s a general outline of the steps involved:

- Turn off the power to the boiler.

- Locate the leak in the expansion vessel.

- Replace the damaged parts, such as the diaphragm or valve.

- Recharge the expansion vessel with the correct amount of water.

- Test the system to ensure that the leak has been fixed and that the pressure is within the correct range.

Conclusion

A combi boiler expansion vessel is a crucial component of your central heating system, but it’s not immune to problems. By understanding the top issues and how to spot them, you can keep your central heating system running smoothly and avoid more significant problems down the line.

Regular checks of your expansion vessel’s pressure and regular replacements can help keep your central heating system in top condition.

Related articles: