Introduction to Boiler Heat Exchangers

Boiler heat exchangers play a critical role in the efficient functioning of your heating system. These devices transfer heat from the combustion process to the water or air, ensuring effective and reliable heating throughout your property. Understanding the different types of heat exchangers and their applications is essential for maximizing energy efficiency and reducing operational costs.

Heat exchangers play a crucial role in boilers, as they transfer heat from the combustion process to the water used for heating. With proper maintenance, the lifespan of heat exchangers in boilers can be significantly extended, leading to more efficient and cost-effective heating.

Types of Boiler Heat Exchangers

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are one of the most common types used in boiler systems. They consist of a cylindrical shell with tubes passing through it. The hot combustion gases flow inside the tubes, transferring heat to the water or air circulating around them. These heat exchangers are known for their versatility, durability, and ability to handle high-pressure and high-temperature applications.

Plate Heat Exchangers

Plate heat exchangers are compact and efficient devices that use a series of plates to transfer heat. The plates have alternating channels through which the hot gases and the fluid to be heated flow, allowing for efficient heat transfer. Plate heat exchangers are widely used in residential and commercial applications due to their space-saving design and excellent heat transfer capabilities.

In a typical gas combi boiler, the plate heat exchanger is the component that quickly heats the hot water needed at the taps and is usually separate from the main heat exchanger that heats water for the central heating radiators.

Finned Tube Heat Exchangers

Finned tube heat exchangers are specifically designed to enhance heat transfer by increasing the surface area available for heat exchange. These heat exchangers consist of tubes with extended fins attached to the outer surface. The fins increase the contact area between the hot gases and the surrounding fluid, improving heat transfer efficiency. Finned tube heat exchangers are commonly used in industrial settings where high heat transfer rates are required.

Factors to Consider When Choosing a Boiler Heat Exchanger

Selecting the right boiler heat exchanger is crucial for optimizing energy efficiency and ensuring long-term reliability. As a boiler user, you will choose the boiler rather that the heat exchanger that comes within it. when speaking to the installer, make the following factors have been considered before making a decision:

Heat Transfer Efficiency

Efficiency is a key consideration when choosing a heat exchanger. Look for models that offer high heat transfer coefficients, ensuring maximum heat exchange between the hot gases and the fluid being heated.

Size and Capacity

The size and capacity of the heat exchanger should be compatible with your boiler system’s requirements. An undersized exchanger may not provide sufficient heat transfer, while an oversized one can lead to excessive pressure drops and increased energy consumption.

Material Selection

The material of the heat exchanger should be carefully chosen to resist corrosion, withstand high temperatures, and ensure longevity. Common materials include stainless steel, copper, and aluminum, each with its own advantages and suitability for specific applications.

Maintenance and Serviceability

Consider the ease of maintenance and accessibility of the heat exchanger when making your selection. A well-designed exchanger will have provisions for cleaning and inspection to ensure optimal performance and longevity.

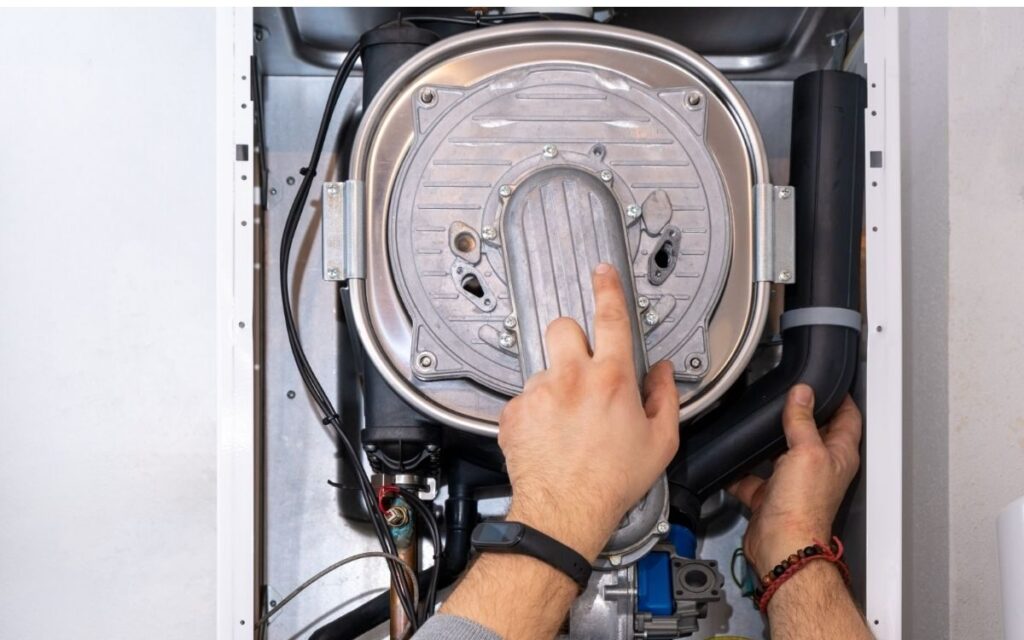

Maintaining Your Boiler Heat Exchanger

Proper maintenance is crucial for the efficient and reliable operation of your boiler heat exchanger. During a boiler service, the following best practices should be followed to ensure optimal performance:

Regular Cleaning

Periodically clean the heat exchanger to remove any deposits or fouling that can hinder heat transfer. Consult the manufacturer’s guidelines for the recommended cleaning procedures and products.

Inspections and Repairs

Schedule routine inspections to identify any potential issues or signs of wear. Promptly address any leaks, cracks, or other damages to prevent further deterioration and ensure the longevity of your heat exchanger.

Water Treatment

Implement an appropriate water treatment program to prevent scale formation and corrosion within the heat exchanger. This will help maintain its efficiency and prolong its lifespan.

Lifespan of boiler heat exchangers

Boiler heat exchangers can last as long as the boiler itself – around 15 years, but poor maintenance, poor initial design and installation, or faulty equipment design can lead to faster failure. Causes of failure include sludge build-up, limescale accumulation, and lack of maintenance. Regular maintenance is crucial for keeping the heat exchanger running efficiently.

Heat Exchangers in different types of boilers

Conventional Boilers

Conventional boilers, also known as traditional or open-vent boilers, have a separate tank for storing hot water. They use a heat exchanger to transfer heat from the combustion process to the water in the tank. The heat exchanger in a conventional boiler is typically made of metal and can be vulnerable to rust and corrosion over time.

Combi Boilers

Combi boilers short for combination boilers, provide both heating and hot water without the need for a separate hot water storage tank. They have a compact design and use a heat exchanger to transfer heat directly to the water that flows through the unit. The heat exchanger in a combi boiler is usually made of stainless steel or other corrosion-resistant materials.

System Boilers

System boilers are similar to conventional boilers, but they have a built-in hot water storage tank. They use a heat exchanger to transfer heat from the combustion process to the water in the tank. The heat exchanger in a system boiler can be made of metal or a corrosion-resistant material, depending on the manufacturer and model.

Condensing Boilers

Condensing boilers are high-efficiency boilers that use a heat exchanger to extract additional heat from the flue gases produced by the combustion process. The heat exchanger in a condensing boiler is typically made of stainless steel or other corrosion-resistant materials. The increased efficiency of a condensing boiler results in lower energy costs and a longer lifespan for the heat exchanger.

Importance of Regular Maintenance for Heat Exchangers in Boilers

1. Clear debris from the heat exchanger

Clearing debris from the heat exchanger is a crucial step in maintaining the longevity of your boiler’s heat exchanger. Debris can accumulate in the heat exchanger over time and reduce its efficiency, leading to higher energy costs and a shorter lifespan.

Regular cleaning of the heat exchanger can help keep it free of debris and functioning properly. Only a qualified gas engineer should do this, usually on a full strip down boiler service.

2. Test for leaks

Testing for leaks in the heat exchanger is an important part of boiler maintenance. Leaks can cause a loss of efficiency and lead to a shorter lifespan for the heat exchanger. Regular testing can help identify leaks early and prevent further damage.

A leaky heat exchanger may have water dripping from the bottom of the casing.

3. Monitor water quality

The quality of the water used in the heating system can have a significant impact on the lifespan of the heat exchanger.

Hard water and high levels of minerals in the water can lead to limescale build up and corrosion, reducing the efficiency and lifespan of the heat exchanger.

Regular monitoring of the water quality and using water treatment products can help prevent these issues.

4. Conduct regular power flushes

A power flush is a process that uses high-pressure water to remove debris and build up from the heating system, including the heat exchanger.

Regular power flushes can help keep the heat exchanger free of debris, reduce the risk of corrosion, and extend its lifespan. Power flushes should be conducted by a professional to ensure they are done correctly and safely.

Common Causes of Heat Exchanger Failure in Boilers

- Rust and corrosion.

- Scale build up.

- Debris accumulation.

- Leaks in the system.

Read our full guide on common causes of heat exchanger problems

Monitoring the pressure gauge and flow rate

Monitoring the pressure gauge for the correct level and water flow rate in your combi boiler is important for the longevity of the heat exchanger.

High water pressure can cause increased wear and tear on the heat exchanger, while low water flow can result in insufficient heating, leading to the boiler staying on for longer.

Regular monitoring of the pressure and water flow rate can help ensure that they are within the recommended range, leading to a longer lifespan for the heat exchanger.

The Benefits of a Long Lasting Heat Exchanger

Increased energy efficiency: By keeping the heat exchanger in your boiler in good working order, you can increase the efficiency of your heating system. This can result in lower energy costs, as your boiler will use less energy to maintain the desired temperature.

Improved heating performance: An efficiently functioning heat exchanger can help improve the performance of your heating system. A well-maintained heat exchanger can transfer heat more effectively, leading to improved heating performance and a more comfortable living environment.

Reduced need for repairs: Regular maintenance and cleaning of the heat exchanger in your boiler can help reduce the need for costly repairs. By preventing issues that can shorten the lifespan of the heat exchanger, you can extend its life and reduce the need for repairs.

Increased safety: A well-maintained heat exchanger in your boiler can reduce the risk of safety hazards, such as leaks and fires. Regular maintenance can help identify and prevent issues before they become serious, leading to a safer living environment.

Increased lifespan of the boiler: By extending the life of the heat exchanger in your boiler, you can also increase the lifespan of the boiler as a whole. A well-maintained heat exchanger can help keep the boiler running efficiently and effectively, leading to a longer lifespan and a lower need for replacement.

Conclusion

In conclusion, a properly selected and well-maintained boiler heat exchanger is essential for efficient heating in residential, commercial, and industrial settings. Understanding the different types of heat exchangers, considering key factors during the selection process, and following proper maintenance practices will ensure optimal performance and long-term reliability.

Heat exchangers play a crucial role in boilers and their longevity can greatly impact the efficiency and cost effectiveness of your heating system. Regular maintenance, using high quality products, and proper installation are just some of the ways to extend the lifespan of heat exchangers in boilers.

By following these steps, you can ensure that your boiler operates at peak performance and saves you money in the long run