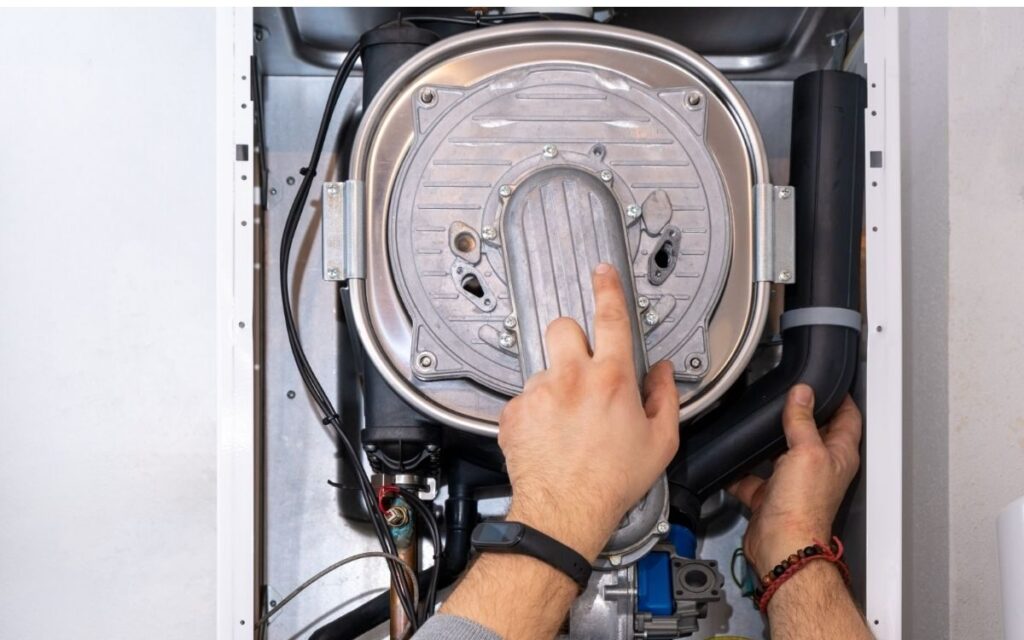

A combi boiler is a popular heating system in many households. It combines the functions of a boiler and a hot water tank into one compact unit. However, like any other heating system, combi boilers can experience problems, including issues with the heat exchanger. In this article, we will discuss the most common heat exchanger problems in combi boilers and how to solve them.

Faulty heat exchanger problems

A boiler heat exchanger transfers heat from the burner to water in a closed loop system, producing hot water and heating. Signs of a faulty heat exchanger include strange noises, leaks, and dirty radiator water. To increase lifespan, have a Gas Safe engineer annually inspect it. Limescale buildup causes damage over time. Causes include:

- Corrosion

- Blockages

- Leaks

- Reduced heating performance

- carbon monoxide release

- Rusty/discoloured water

- Water damage

The heat exchanger in a combi boiler is exposed to high temperatures, which can cause it to corrode over time. This can lead to leaks and reduced efficiency in your heating system.

The lifespan of a boiler and heat exchanger in the UK before needing replacement

1. Corrosion of the Heat Exchanger

Corroded heat exchangers can lead to leaks, reduced efficiency, and even complete failure of your heating system. In this article, we will discuss the dangers of corroded heat exchangers in combi boilers and how to prevent them.

What is a Corroded Heat Exchanger?

A heat exchanger is a component in a combi boiler that transfers heat from the burning fuel to the water used for heating. Over time, the heat exchanger can become corroded due to exposure to high temperatures, moisture, and chemical reactions. This corrosion can lead to cracks and holes in the heat exchanger, which can cause leaks and reduce the efficiency of your heating system.

Symptoms of a Corroded Heat Exchanger:

- Reduced heating performance

- Strange noises, such as rattling or knocking

- Leaks in the heating system

- Rusty or discolored water

- Increased heating bills

Why is a Corroded Heat Exchanger Dangerous?

A corroded heat exchanger can pose serious safety risks, including the release of toxic gases, such as carbon monoxide, into your home. Carbon monoxide is an odourless, colourless gas that can cause illness or death if inhaled. In addition, a leaking heat exchanger can lead to water damage, mould growth, and other structural problems in your home.

Prevention and Solution

The best way to prevent corrosion of the heat exchanger in your combi boiler is to have regular maintenance performed by a professional. This may include:

- Flushing the system to remove debris and limescale buildup.

- Fitting a magnetic filter onto the system

- Checking for leaks and tightening connections

- Replacing old or worn components

- Descaling the system to remove limescale buildup

If you suspect that your heat exchanger is corroded, it’s important to call a professional for an inspection. In severe cases, the heat exchanger may need to be replaced to ensure safe and efficient heating for your home. Regular maintenance can help prolong the life of your heat exchanger and prevent dangerous and costly problems from occurring.

Corroded heat exchangers in combi boilers can pose serious safety risks and reduce the efficiency of your heating system. If you suspect that your heat exchanger is corroded, don’t hesitate to call an engineer for an inspection and repairs.

On a full service, the heat exchanger will be flushed out so it is in tip top shape. However, most boiler service routines nowadays tend not to include it. Ask the heating engineer what type of service will they be doing.

Troubleshooting steps for boilers not working properly such as no hot water

2. Blockages in the Heat Exchanger

The heat exchanger in a combi boiler transfers heat from the burning fuel to the water used for heating. Blockages in the heat exchanger can restrict the flow of water, leading to reduced efficiency and even complete failure of your heating system. Blockages can be caused by sludge, debris and limescale build up in your system.

Symptoms of Blockages in the Heat Exchanger:

- Reduced heating performance

- Poor hot water pressure

- Strange noises, such as knocking or whistling

- Leaks in the heating system

- Increased heating bills

Early warning signs that your boiler and heat exchanger may be failing

Why are Blockages in the Heat Exchanger Dangerous?

Blockages in the heat exchanger can not only reduce the efficiency of your heating system, but they can also cause complete failure of your system. In addition, blockages can cause damage to your system, leading to costly repairs.

Prevention and Solution

The best way to prevent blockages in the heat exchanger in your combi boiler is to have annual servicing performed by a professional.

If you suspect that your heat exchanger is experiencing blockages, it’s important to call a professional for an inspection. A professional can flush the heat exchanger to remove blockages and restore efficiency. Regular maintenance can help prevent blockages from forming in the first place.

3. Leaks in the Heat Exchanger

Leaking heat exchangers can lead to reduced heating performance and can also be a safety hazard. A leaking heat exchanger can cause water damage, mould growth, and other structural problems in your home. Leaks can be caused by corroded or damaged heat exchangers, blockages, and other issues.

Why is a Leaking Heat Exchanger Dangerous?

In addition to causing damage to your home, a leaking heat exchanger can pose serious safety hazards, such as the release of toxic gases, such as carbon monoxide, into your home. Carbon monoxide is an odourless, colourless gas that can cause illness or death if inhaled.

If you suspect that your heat exchanger is leaking, it’s important to call a professional for an inspection. A professional can identify the source of the leak and perform repairs to prevent further damage to your home and heating system. In severe cases, the heat exchanger may need to be replaced.

Why parts like the heat exchanger failing can lead to expensive boiler breakdowns

4. Sludge build up in the system

Sludge in a heating system is typically made up of a mixture of mineral deposits, corrosion by products, and other debris that accumulates over time.

When sludge accumulates in the boiler, it can clog the heat exchanger, reducing its ability to transfer heat effectively. This can result in a colder home, increased energy bills, and reduced heating system efficiency.

In addition to reducing heating performance, sludge build up in the heat exchanger can also cause damage to the component over time. As the sludge continues to accumulate, it can cause corrosion, leaks, and other problems that can further reduce the efficiency of the heating system and pose a safety hazard to your home.

Sludge can contain among other things:

- Mineral deposits, such as calcium and magnesium

- Corrosion byproducts, such as rust particles

- Flux from jointing of copper pipes

- Dirt and sediment

- Debris from the surrounding environment

- Impurities from the water supply, such as iron and manganese

- Residues from chemical treatments, such as inhibitors and cleaning agents

Maintaining and Repairing Heat Exchangers

Preventive Maintenance

To ensure optimal performance of your heat exchanger, it is important to conduct regular preventive maintenance. This involves checking for any signs of wear and tear, cleaning the exchanger, and replacing any damaged or worn-out parts. Here are some tips for preventive maintenance:

- Regularly inspect the heat exchanger for any signs of corrosion, cracks, or leaks.

- Clean the heat exchanger regularly to prevent the build-up of dirt, debris, and scale.

- Replace any damaged or worn-out parts such as gaskets, seals, and tubes.

- Ensure that the heat exchanger is properly installed and secured.

By conducting regular preventive maintenance, you can extend the lifespan of your heat exchanger and prevent costly repairs.

Items to inspect during boiler servicing to identify potential heat exchanger faults

Common Repair Methods

Despite regular preventive maintenance, your heat exchanger may still require repairs at some point. Here are some common repair methods:

- Tube Replacement: If the tubes in your heat exchanger are damaged or corroded, they may need to be replaced. This involves removing the damaged tubes and installing new ones.

- Gasket Replacement: If the gaskets in your heat exchanger are worn out or damaged, they may need to be replaced. This involves removing the old gaskets and installing new ones.

- Chemical Cleaning: If your heat exchanger is heavily fouled with dirt, debris, or scale, it may require chemical cleaning. This involves using a chemical solution to dissolve the fouling material and clean the exchanger.

- Welding: If there are any cracks or leaks in your heat exchanger, they may need to be repaired through welding. This involves welding the damaged area to seal any leaks or cracks.

It is important to hire a qualified engineer to conduct any repairs on your heat exchanger. Attempting to repair the exchanger yourself can be dangerous and may cause further damage.

Is it better to replace a faulty heat exchanger or get a new boiler?

The cost of replacing a heat exchanger will vary depending on the make and model of the boiler and the size of the heat exchanger, but typically it can range from £400 to £800. Replacing a combi boiler can be much more expensive, with costs for the boiler itself ranging from £800 to £2,000, and additional installation costs of around £1,000.

The answer to whether it’s better to replace a faulty heat exchanger or get a new boiler depends on several factors. Some factors to consider include:

- Age of the boiler: If your boiler is relatively new, it may make more sense to replace the heat exchanger and keep the rest of the system intact. However, if your boiler is older and experiencing frequent problems, it may be more cost-effective to replace the entire system.

- Energy efficiency: If your old boiler is not energy-efficient, it may be more cost-effective in the long run to replace it with a new, high-efficiency boiler.

- Safety: If your old boiler is a safety hazard, such as due to a leaking heat exchanger, it’s important to replace it as soon as possible to protect your family and home.

Heat Exchanger in Boiler – FAQ

Q: What are the symptoms of a faulty heat exchanger in a boiler?

A: Symptoms of a faulty heat exchanger in a boiler may include reduced heating performance, inconsistent hot water supply, strange noises, leaks, or a drop in boiler pressure. It is important to have a qualified heating engineer inspect and diagnose the issue.

Q: What are some common problems with heat exchangers?

A: Common problems with heat exchangers include corrosion, leaks, cracks, blockages, or a buildup of sediment. These issues can impact the efficiency and functionality of the boiler and should be addressed by a professional.

Q: How do I know if my heat exchanger is faulty?

A: Signs of a faulty heat exchanger may include a significant drop in boiler efficiency, inconsistent heating or hot water, unusual smells, visible leaks or corrosion on the heat exchanger, or the presence of carbon monoxide. Contact a heating engineer for an accurate assessment.

Q: What causes a heat exchanger in a boiler to fail?

A: Several factors can cause a heat exchanger in a boiler to fail, including corrosion due to water chemistry issues, improper installation, excessive strain from high-pressure levels, or lack of regular maintenance. Consult a professional to identify the specific cause and solution.

Q: What are the typical costs for replacing a heat exchanger in a combi boiler?

A: The cost of replacing a heat exchanger in a combi boiler can vary depending on factors such as the boiler model, complexity of the installation, and labor charges. It is recommended to obtain quotes from qualified engineers for an accurate cost estimate.

Q: What are some common faults with Worcester Bosch heat exchangers?

A: Common faults with Worcester Bosch heat exchangers may include leaks, blockages, or issues with the diverter valve. Consulting a Worcester Bosch accredited engineer is advisable to diagnose and resolve specific faults with their heat exchangers.

Related articles: