If you’re experiencing problems with your Viessmann combi boiler and the hot water is goes cold or lukewarm, before getting hot again, you are not alone. This is a common issue with Viessmann boilers with the main issue being a blockage in the hot water heat exchanger. But there can be a variety of other causes. Here, we look at the most common reasons.

Common Viessmann Boiler Problems

- Low boiler pressure

- Faulty components like fan, PCB, pump

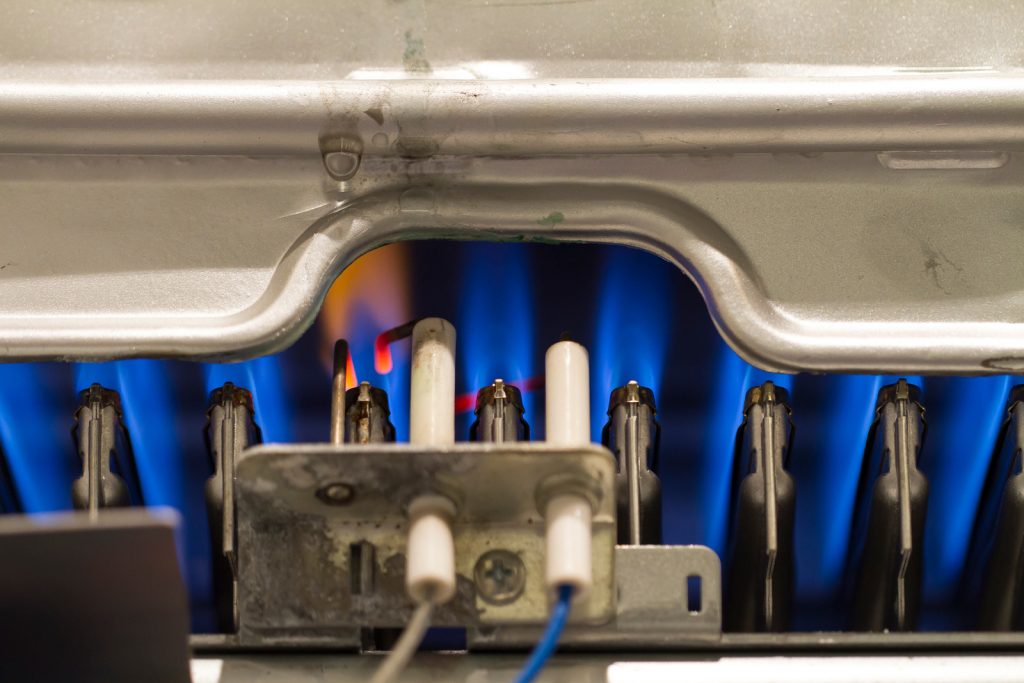

- Burner faults

- Pilot light going out

- Noisy boiler operation

- Corroded heat exchanger

- Fault codes appearing

Causes of Viessmann Boiler Problems

Scaled up heat exchanger

A blocked up heat exchanger, partially or fully with scale, will cause hot and cold water problems. The boiler will struggle to reach temperature and will be more likely to overheat, which can lead to component breakdown.

If caught early, the plate heat exchanger can be removed and cleaned out. Otherwise, if completely blocked, it will need to be replaced, and that isn’t exactly cheap.

Sludge in the plate heat exchanger

This issue is relevant to Viessmann boilers. Similar to a blockage caused by scale, sludge in the plate heat exchanger restricts hot water flow through the component, at first causing intermittent hot water. Eventually, the hot water will stop and you will get only cold water.

Slow water flow

Another possibility is that there’s an issue with the water flow rate – if it’s too low, the boiler will struggle to heat up properly and will keep cycling on and off. Again, this is something that an engineer will be able to help you with.

Water flow is too fast

On the other hand, if the water is running through the boiler too fast, the system doesn’t get the chance to heat the water up enough.

The boiler engineer will be able to adjust the valve after doing the necessary checks to adjust the flow rate through the boiler. Slowing the water rate will heat it up much better.

Faulty thermistor

An issue common with Viessmann boilers is a faulty thermistor. Here, it doesn’t gauge the correct temperature of the water and so allows the water to get overly hot. Other sensors in the boiler pick this rise up and shut down the boiler, making the water go cold. This cycle then repeats often.

Faulty shower control thermostat

If your hot water suddenly starts going cold or lukewarm, check whether it is only at the one outlet or with multiple. Water being lukewarm or tepid at just one outlet, usually the shower, indicates a faulty thermostat on the shower. Check with a nearby hot tap to make sure.

Preheated water in the boiler

Viessmann combi boilers, taking water directly from the mains to heat up, will always have some hot water in the boiler, whether preheated or not. So when a tap is turned on, you will get one or two seconds of hot water, then cold water coming through the pipes before the boiler plays catch up and delivers heated water.

Pressure relief valve

If your boiler is cycling on and off frequently, it could be due to a number of reasons. One possibility is that the pressure relief valve (PRV) is set too low. This can cause Viessmann boilers to overheat and trip the safety switch, leading to the boiler shutting down.

If you think this might be the case, you should call in a Gas Safe registered engineer to take a look.

Fixing Viessmann Boiler Problems

Many common Viessmann boiler problems can be fixed by the homeowner, while others require a professional Gas Safe registered engineer. Here are some troubleshooting tips and solutions for common issues.

Low Boiler Pressure

If the pressure gauge on your Viessmann boiler reads below 1 bar, the pressure is too low. This can cause the boiler to cut out.

To increase the pressure:

- Locate the filling loop, which is usually under the boiler

- Attach the filling loop if it is detachable

- Slowly open the valves on the loop to let water in

- When pressure reaches 1-1.5 bar on the gauge, close valves

- Disconnect filling loop

This simple fix will restore operating pressure. If pressure drops frequently, a leak may exist in the system.

Radiators Not Heating Fully

Radiators that are cold at the bottom need bleeding to remove trapped air. Use a radiator key to open the bleed valve at the top of the radiator. Close it when water starts dripping out.

If radiators are only lukewarm throughout, a pump or sensor fault may exist. An engineer will need to test components and replace any that are faulty.

Noisy Boiler

Noisy boilers often have an issue with the pump or need descaling from limescale buildup. Try bleeding all radiators in case air is trapped. Have an engineer inspect the pump and descale if needed.

Fault Codes

Whenever a fault code appears on your Viessmann boiler display, check the code against the user manual to diagnose the issue. Fault codes provide useful troubleshooting information.

| Fault Code | Issue | Solution |

|---|---|---|

| F1 | Burner blocked | Replace flue gas sensor |

| F2 | Burner lockout | Check/clean pump, check airlocks |

| F5 | Boiler won’t ignite | Clean/test air pressure sensor |

If in doubt, call an engineer for faults indicated as needing a professional.

Annual Service

Many minor faults can be prevented through annual servicing of your Viessmann boiler by a Gas Safe registered engineer. This includes inspection of all components and cleaning/adjustment as required.

Regular maintenance is essential for continued efficient operation and reliability of your Viessmann boiler.

Boiler Replacement

For persistent issues or when a boiler is over 10-15 years old, a complete boiler replacement often makes better financial sense than continuing with costly repairs.

When getting quotes for a new Viessmann boiler, ensure the price includes professional installation for optimal efficiency, safety, and peace of mind.

Conclusion

Some of the most common Viessmann boiler problems include no hot water, the boiler not firing up, low pressure, faulty components like the fan or PCB, radiators not heating fully, and new boilers not starting.

Low pressure can be fixed by repressurising via the filling loop. Bleeding radiators can fix airlocks. Frozen condensate pipes need thawing. Faulty parts like pumps, sensors, and thermostats require replacement by an engineer.

For issues like burner faults and pilot lights going out, a Gas Safe registered engineer will need to service the boiler and replace damaged sections. Leaks should be repaired immediately before causing more severe issues.

Regular servicing, maintaining boiler pressure, and bleeding radiators can prevent many Viessmann boiler problems. But issues like leaks, corrosion, and faulty components will inevitably occur over time. When repair costs become excessive, replacing the boiler may be the better solution.